From Oil and Gas to manufacturing, construction to mining, while the ‘fourth industrial revolution’ galvanized safety providers to embrace digitization, the ‘fifth Industrial revolution’ put the human at the center of all the technology. United Safety has been on the forefront of all these developments. Through TeQ Shield™, its portfolio of digital safety and productivity services, United Safety has been working to develop and rent cutting-edge safety solutions that enhance worker safety and productivity while optimizing costs for the organization.

What is TeQ Shield™?

TeQ Shield™ is an integrated suite of safety and productivity services that use IIoT and the latest digital technology to enhance safety, efficiency and productivity of onsite workers.

TeQ Shield™ services include the rental of electronic confined space monitoring, remote equipment automation, real time location services, cloud-based safety services, connected worker solutions, productivity applications, digital permits, advanced data analytics, computer vision, artificial intelligence, robotics solutions, augmented reality, virtual reality and digital inspections.

The result? Improved productivity through enhanced visibility, informed decision making using real time data and lower costs in a safer environment.

TeQ Shield™ Guardian

Remote Confined Space Monitoring System.

TeQ Shield™ Hub

Central point of service distribution. Includes In Plant Equipment Center and TeQ Shield™ IIoT.

Teq Shield™ Connected Worker

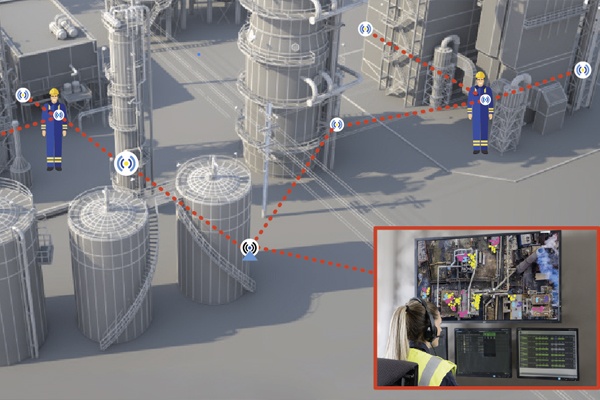

Services that transform a regular workforce to a connected workforce. Includes real-time tracking and monitoring, and other IIoT-based services.

TeQ Shield™ AI

AI and computer vision services that monitor and ensure compliance to certain safety services and protocols

TeQ Shield™ Robotics

Robots can be sent to perform hazardous tasks that would have otherwise required a human worker.

The TeQ Shield™ family currently encompasses:

TeQ Shield™ 360

Multiple devices, unified platform

Introducing TeQ Shield™ 360. A unified, safety platform that integrates all your smart, safety devices onto one platform. The result? You can now manage multiple safety operations, monitor different workers, control access in real time, track workers and assets, check biometrics and perform a host of other safety related functions – from one centralized platform.

TeQ Shield™ Guardian

Remote Confined Space Monitoring System.

Our centralized confined space monitoring system – TeQ Shield™ Guardian combines gas detection, video cameras, two-way communication and access control to create an effective rental solution for confined space monitoring.

TeQ Shield™ Guardian. Making confined spaces and hazardous environments safer and more productive.

TeQ Shield™ Hub

Central point of service distribution.

TeQ Shield™ Hub is a family of digital services that constitute the core or the central aspect of a service. Two main services provided under this cluster include:

TeQ Shield™ AIPEC

TeQ Shield™ AIPEC (Automated In-Plant Equipment Center) is the central point of onsite distribution in any facility or refinery.

TeQ Shield™ IIoT

TeQ Shield™ IIoT is a central general-purpose IIoT platform that supports multiple devices, offers first-class support for Real time Location Systems (RTLS) and GIS services and provides Secure Data Asset Management (DAM) for streaming and recorded media.

TeQ Shield™ Connected Worker

As the name suggests, this cluster of services transforms a regular workforce to a connected workforce. Key services under this cluster include:

TeQ Shield™ Tracker

These are RTLS-based solutions with a wide range of applications including real time personnel and asset tracking, emergency mustering, geo-fencing, vehicle collision avoidance etc.

Communicator

A smart industrial hard hat that enables real-time monitoring and tracking and two-way communication between the command center and workers.

Scout

A ruggedized, small, wearable device with a touch display. The Scout is ideal for location-tracking, proximity-detection, audio-visual communication, and core worker safety features.

TeQ Shield™ Ready-for-Duty-Services

A comprehensive suite of solutions that help organizations improve employee safety and create operational efficiencies.

TeQ Shield™ AI

In recent years, AI has been playing a growing role in revolutionizing safety for the Oil and Gas industry. From monitoring PPE compliance to fall detection, there are numerous ways that AI is being used to improve workplace safety. At United Safety, we focus on two main areas where AI has the greatest impact:

TeQ Shield™ Analytics

TeQ Shield™ Analytics uses AI to go through data to give you insights into various aspects of your business. From enhancing productivity to enabling better planning and mitigating risk factors, understanding and analyzing data generated can result in numerous value-added benefits for the company.

TeQ Shield™ Computer Vision

Computer Vision is a field of AI that enables computers and systems to ‘see’, observe and derive meaningful information from digital images and videos. It enables computers to take actions or make recommendations based on the information received.

TeQ Shield™ Robotics

Advanced capability, superior intelligence

There is a growing trend to use robots to provide onsite safety solutions. In the Oil and Gas industry, robots can be used to perform hazardous jobs that are usually performed by workers making it safer for the workforce. This can range from equipping robots with gas detectors to check for toxic gas leaks to carrying hazardous materials or conducting dangerous and monotonous tasks.